Available for trials

Lamiflex E

High level duplex solventless laminator for widest range of substrates

850/1320 mm

33.5/52"

Web width

400 m/min

1312 fpm

Speed

1000 mm / 1000 kg

39.4"/2204.6 lbs

Roll diameter / weight

solventless

solventless

Lamination type

Processed materials: BOPP, PET, PE, LDPE, OPA, CAST PP, CAST PA, AL foil, paper, laminate and more

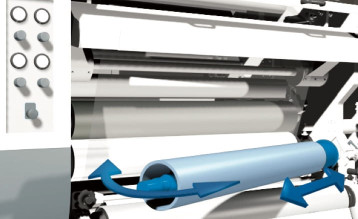

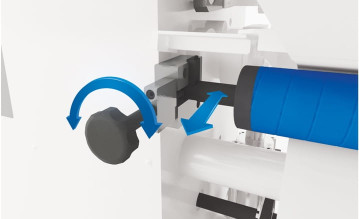

Sleeved transfer roller

The cantilevered sleeved transfer roller enables very quick and easy on-board sleeve exchange.

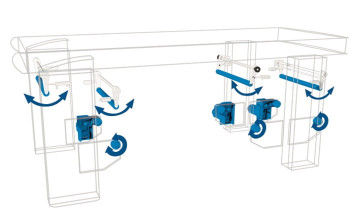

Shaft-less unwind and rewind units

Shaft-less unwind and rewind units enable quick, easy and comfortable roll clamping horizontally.

Temperature control

Three loops with individual thermo-controlled units for dosing rollers, application roller and the the lamination roller ensure the higher speed running and increase the options for processing a wide range of substrates.

Tension control

Lamiflex E is designed to process a wide range of substrates with tension range 20 - 400 N at unwind and 20 - 500 N at rewind offers laminating of thin and difficult materials.

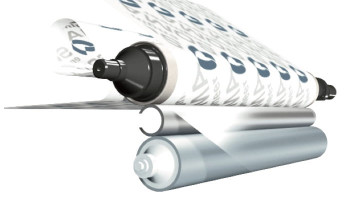

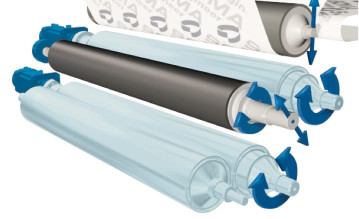

Three-roller lamination

High quality lamination is ensured by a three roll system that ensures high rigidity, a small rubber contact area and a large angle of incoming material for perfect lamination and air bubble elimination in the final laminate.

Glue application

Precise glue application rollers, high rigid mechanical stop of the dosing gap and fixed roller housing enable precise and constant glue dosing.

Automatic web guiding

Automatically controlled horizontal movement of unwind units and materials ensures high rewind quality of poor-quality input rolls.

Angle adjustable rollers

Adjustable guide rollers at unwind and rewind balance the poor-quality (conical) input rolls can be successfully processed.

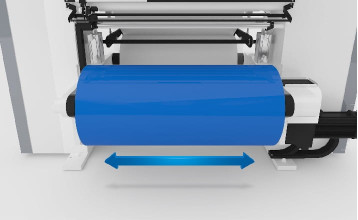

Cooling cylinder

A water cooled cylinder ensures laminate cooling before rewinding and contributes in eliminating roll telescoping.

Fume exhausting

A high efficiency exhaust system over the whole machine width reliably removes all fumes.

Mixing and dosing unit

Simple dosing solution for one-component and two-component glue with full automated refilling directly from barrels ensures smooth glue dosing with minimal manual handling.

Recipe system

All machines are equipped with a recipe system for job file storage to be easily recalled from the memory.

Roller wash-up

Automatic roller pre wash-up of transfer sleeved and application rollers significantly reduces costs and saves the operator time at the end of each job.

Intuitive control

A touch screen control panel with user friendly interface.

CE standards

Machines comply with and meet stringent European safety standards and codes.

High level duplex solventless laminator for widest range of substrates

Web width

850/1320 mm

33.5/52"

Speed

400 m/min

1312 fpm

Roll diameter / weight

1000 mm / 1000 kg

39.4"/2204.6 lbs

Lamination type

solventless

solventless

Min. web width

300 mm

11.8"

Processed materials

BOPP, PET, PE, LDPE, OPA, CAST PP, CAST PA, AL foil, paper, laminate and more

BOPP, PET, PE, LDPE, OPA, CAST PP, CAST PA, AL foil, paper, laminate and more

Eager to get more information?

×

Top

SOMA spol. s r.o.

B. Smetany 380melegattim@soma-eng.com

Tecnimprensa, S.A.

Rua do Visconde de Bóbeda 36alvesdesousa@tecnimprensa.pt

Coras S. A.

Billinghurst 1833gabriels@coras.com.ar

VIP-Systems Graphische Maschinen GmbH

Mr. Sergey Spilkasvs@vipsys.ru g.franz@vipsystems.de

TCL Hofmann

150 Woodlands DriveT.Hardy@tclhofmann.com.au

D-Flex e.U.

RossauerLände 33/31henn@d-flex.at

VIP-Systems Graphische Maschinen GmbH

Mr. Sergey Spilkasvs@vipsys.ru g.franz@vipsystems.de

SOMA spol. s r.o.

B. Smetany 380sales@soma.cz www.soma-eng.com

Galred Europe BV

Centurionbaan 60-07info@galred.com

SOMA spol. s r.o.

B. Smetany 380acuy@soma.cz

SOMA spol. s r.o.

B. Smetany 380dresler@soma.cz

Coras do Brasil

Rua Dr. Luiz Miglianog.virginillo@coras.com.br

SOMA spol. s r.o.

B. Smetany 380kracmar@soma-eng.com

Rieckermann (Cambodia) Co. Ltd.

City Tower #321, Street 245,phnompenh@rieckermann.com

DTM Flexo Services

Second Street North 27dave.mcbeth@dtmflexo.com service@soma-eng.com

Comercial Andexport

Blvd. Aeropuerto Nte. 9627vitonapoli@andexport.com

ANOKA M&E ENGINEERING CO., LTD.

Room 1001, Liyuan, Yihao Gongguan, Baoli Shuicheng, No.2 Denghu Xilu, Nanhai Districtjima.zhu@apet.com.hk

Representaciones Cosalco S.A.

Bodega 28, Portos Sabana 80 # 28ssalazar@cosalco.com

Representaciones Cosalco S.A.

Ofibodegas Comerciales Logic Park no. 25, Calle Potrerillos, Provincia de Alajuelaggonzalez@cosalco.com

Kliše - Kop

Dr. Franje Tuđmana 39roman@klise-kop.hr

Headquarters

Husova 78

Production facilities

B. Smetany 380

SCANTECO APS

Walgerholm 7jens@scanteco.dk

Representaciones Cosalco S.A.

Ofibodegas Comerciales Logic Park no. 25, Calle Potrerillos, Provincia de Alajuelaggonzalez@cosalco.com

Paúl Piedra

Los Olivos no. 64 y Josefina Barba, Sector Capelopapiedraa@gmail.com

DELTA TRADING & COMMERCIAL AGENCIES Ltd.

64, Abo Elfotoh Buildings pyramids Roadm.shaban@deltatrading-eg.com

Representaciones Cosalco S.A.

Ofibodegas Comerciales Logic Park no. 25, Calle Potrerillos, Provincia de Alajuelaggonzalez@cosalco.com

Nuera UAB

Virsilu str. 13-59info@nuera.lt

MARS PACKAGING AFRICA LTD.

Yakuti close, Road 'A' Enterprise roadlokesh@marsme.ae

SCANTECO APS

Walgerholm 7jens@scanteco.dk

SOMA spol. s r.o.

B. Smetany 380sales@soma.cz www.soma-eng.com

VIP-Systems Graphische Maschinen GmbH

Mr. Sergey Spilkasvs@vipsys.ru g.franz@vipsystems.de

D-Flex e.U.

RossauerLände 33/31henn@d-flex.at

TTS TEXTILE AND TECHNICAL SERVICES LTD

15/17 Abimbola Street, Isolo Industrial Estatedavid@ttsltd.co.uk

Tsolakos-Flexosign

Thionis 7filippos@tsolakos.eu

Representaciones Cosalco S.A.

Ofibodegas Comerciales Logic Park no. 25, Calle Potrerillos, Provincia de Alajuelaggonzalez@cosalco.com

Representaciones Cosalco S.A.

Ofibodegas Comerciales Logic Park no. 25, Calle Potrerillos, Provincia de Alajuelaggonzalez@cosalco.com

B+K Papír- Nyomdaipari és Kereskedelmi KFT.

Szabo Imre u. 47bplusk@axelero.hu

SCANTECO APS

Walgerholm 7jens@scanteco.dk

SOMA India

507, Lodha SIGNET -Akulkarni@soma-eng.com

Rieckermann(SL) Rep. Office

Menara Bidakara 2, 11th floorjakarta@rieckermann.com

SOMA spol. s r.o.

B. Smetany 380sales@soma.cz

SOMA spol. s r.o.

B. Smetany 380maleko@soma-eng.com

NIRPLEX Exclusive Agencies

23 Hamelacha st.uri@nirplex.co.il

SOMA spol. s r.o.

B. Smetany 380melegattim@soma-eng.com

SOMA spol. s r.o.

B. Smetany 380melegattim@soma-eng.com

SOMA spol. s r.o.

B. Smetany 380melegattim@soma-eng.com

DKSH Japan K. K.

Technical Service Center, AE5-7 Tokyo Ryutsu Center, 6-1-1, Heiwajima, Ota-kuhideya.shinagawa@dksh.com

SOMA spol. s r.o.

B. Smetany 380maleko@soma-eng.com

VIP-Systems Graphische Maschinen GmbH

Mr. Sergey Spilkasvs@vipsys.ru g.franz@vipsystems.de

ACE Performance Chemicals & Materials

114 Runda Drivesharonrego@me.com

Rieckermann (Korea) Ltd.

8th Fl., 314, Teheran-ro, Gangnam-guseoul@rieckermann.com

SOMA spol. s r.o.

B. Smetany 380maleko@soma-eng.com

VIP-Systems Graphische Maschinen GmbH

Mr. Sergey Spilkasvs@vipsys.ru g.franz@vipsystems.de

Nuera UAB

Virsilu str. 13-59info@nuera.lt

DYNAGRAPH group

Jisr El Bacha, Hazmiehizeitoun@dynagraph.net

Nuera UAB

Virsilu str. 13-59info@nuera.lt

Galred Europe BV

Centurionbaan 60-07info@galred.com

TOYO LTD

10, Robinson Road No. 2 Phoenix Mauritiustoyoltd@gmail.com

Rieckermann (Malaysia) Sdn. Bhd.

B2-9-01 & B2-9-02, Block B2,kualalumpur@rieckermann.com

TOYO LTD

10, Robinson Road No. 2 Phoenix Mauritiustoyoltd@gmail.com

Tween Chemical Products SAS

Av. de La Industria, San Jeronimo Chicahualcodaniel.martin@acsglobal.org

VIP-Systems Graphische Maschinen GmbH

Mr. Sergey Spilkasvs@vipsys.ru g.franz@vipsystems.de

GRAPHIC ARTS

Rue 8601, No. 35 Zone Industrielle Charguia 1graphic@planet.tn

Tecnimprensa, S.A.

Rua do Visconde de Bóbeda 36alvesdesousa@tecnimprensa.pt

Rieckermann Services Ltd. (Myanmar Representative Office)

No. 499, Room (602), 6th Floor, Pyay Yeik Thar Condo,yangon@rieckermann.com

SOMA spol. s r.o.

B. Smetany 380dresler@soma.cz

Galred Europe BV

Centurionbaan 60-07info@galred.com

TCL Hofmann

150 Woodlands DriveT.Hardy@tclhofmann.com.au

TTS TEXTILE AND TECHNICAL SERVICES LTD

15/17 Abimbola Street, Isolo Industrial Estatedavid@ttsltd.co.uk

SCANTECO APS

Walgerholm 7jens@scanteco.dk

Anoop Plastic Products

Industrial Area 11gandhi@anoop.ae

IR GROUP

Office 809, 8 th Floor, Plot 189/A, Portway Trade Centerir@irgroup.com.pk

Representaciones Cosalco S.A.

Ofibodegas Comerciales Logic Park no. 25, Calle Potrerillos, Provincia de Alajuelaggonzalez@cosalco.com

SOMA spol. s r.o.

B. Smetany 380acuy@soma.cz

SOMA spol. s r.o.

B. Smetany 380acuy@soma.cz

Rieckermann Philippines Inc.

89, West Capitol Drive Brgymanila@rieckermann.com

EMIPAK SP. z o. o.

Al. Jerozolimskie 202zbohdan@emipak.com.pl

Tecnimprensa, S.A.

Rua do Visconde de Bóbeda 36alvesdesousa@tecnimprensa.pt

Anoop Plastic Products

Industrial Area 11gandhi@anoop.ae

TOYO LTD

10, Robinson Road No. 2 Phoenix Mauritiustoyoltd@gmail.com

SOMA spol. s r.o.

B. Smetany 380kracmar@soma-eng.com

PRINTECH MIDDLE EAST LLC

Warehouse no 7.pankaj.patel@printechme.com

SOMA spol. s r.o.

B. Smetany 380dresler@soma.cz

Rieckermann (Singapore) Pte. Ltd.

#06-30/31 Interlocal Centre,singapore@rieckermann.com

Sabre Equipment cc

29 A Quentin Smythe Road, Po box 1387sales@sabreequipment.co.za

SOMA spol. s r.o.

B. Smetany 380sales@soma.cz www.soma-eng.com

Grupo Impryma

Camino de las Rejas,felix.prieto@grupoimpryma.com

SOMA spol. s r.o.

B. Smetany 380sales@soma.cz www.soma-eng.com

SCANTECO APS

Walgerholm 7jens@scanteco.dk

D-Flex e.U.

RossauerLände 33/31henn@d-flex.at

SOMA spol. s r.o.

B. Smetany 380maleko@soma-eng.com

YAH SHENG CHONG YUNG KEE CO., LTD.

6 FL. 109. Jen-Ai road, Sec. 4, Jen Ai Rd.james@twysc.com

VIP-Systems Graphische Maschinen GmbH

Mr. Sergey Spilkasvs@vipsys.ru g.franz@vipsystems.de

SOMA spol. s r.o.

B. Smetany 380melegattim@soma-eng.com

Rieckermann (Thailand) Co. Ltd.

438/3-8 Moo 5, Srinakarin Roadbangkok@rieckermann.com

GRAPHIC ARTS

Rue 8601, No. 35 Zone Industrielle Charguia 1graphic@planet.tn

Grupak Plastik Makineleri İç ve Dış Ticaret Ltd. Şti.

Mahmutbey, İSTOÇ 45 ADA NO.18kerem@grupak.com info@grupak.com

VIP-Systems Graphische Maschinen GmbH

Mr. Sergey Spilkasvs@vipsys.ru g.franz@vipsystems.de

SOMA spol. s r.o.

B. Smetany 380melegattim@soma-eng.com

SOMA spol. s r.o.

B. Smetany 380malek@soma-eng.com maleko@soma-eng.com

Anoop Plastic Products

Industrial Area 11gandhi@anoop.ae

Redfern Machinery Ltd

12 Kayfieldsrichard.redfern@redfernmachinery.com ken.redfern@redfernmachinery.com

SOMA North America

SOMA North Americataylor@soma-eng.com jeff@mmprintingsolutions.com service@soma-eng.com

Coras S. A.

Billinghurst 1833gabriels@coras.com.ar

VIP-Systems Graphische Maschinen GmbH

Mr. Sergey Spilkasvs@vipsys.ru g.franz@vipsystems.de

General Drives

Av. Ppal Colina de Bello Monte; C.C. Bello Monteluciano.galuppo@gmail.com generaldrives.ve@gmail.com

Rieckermann Vietnam Co. Ltd.

7th Floor, VG Buildinghanoi@rieckermann.com

Rieckermann Vietnam Co. Ltd. Branch Office

16th Floor, Tower B, Viettel Trade Centerhochiminhcity@rieckermann.com

SOMA spol. s r.o.

B. Smetany 380maleko@soma-eng.com

SOMA spol. s r.o.

B. Smetany 380melegattim@soma-eng.com